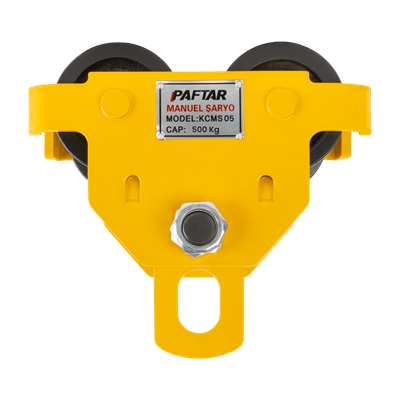

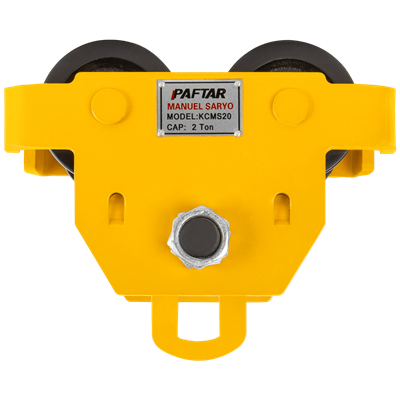

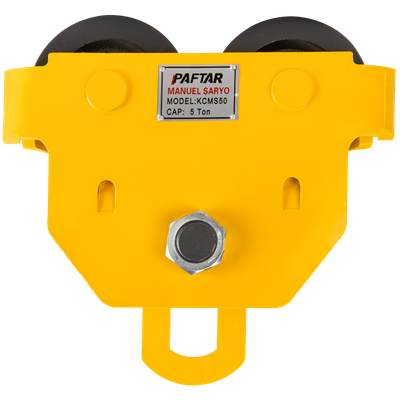

TROLLEY

Trolley Crane is widely used in industrial sectors such as construction, shipyard, warehousing and manufacturing, offering a wide range of applications.

It is an effective solution in every area where heavy loads need to be lifted and transported.

PAFTAR Trolley Cranes are designed in accordance with the highest safety standards. Strong and durable construction materials, modern control systems and user-friendly design ensure a safe use for those who use them. It is also important to ensure that the cranes operate safely and efficiently with regular maintenance and periodic checks.

Important factors to be considered in the use and maintenance of the Trolley Crane are as follows:

1. Proper Use: The Trolley Crane must be used in accordance with the specified carrying capacity. The instructions and safety rules on the crane must be followed carefully. Lifting heavy loads above the limits may pose a risk to the crane and occupational safety.

2. Periodic Maintenance: Trolley Cranes should be subjected to regular periodic maintenance. This maintenance helps to prevent possible malfunctions in the crane and ensures a long-lasting performance. Maintenance operations should be carried out in the periods specified by PAFTAR.

3. Safety Checks: Before each use, safety checks must be made on the crane. The condition of the hook, ropes, brake systems and other important parts should be reviewed. In case of any abnormality or damage, the crane should not be used and the maintenance team should be notified immediately.

4. Attention to Environmental Factors: Environmental factors must be taken into consideration when using the Trolley Crane. Weather conditions such as wind, rain, snow may affect crane operation. Appropriate precautions must be taken and work must be stopped if necessary.

5. Emergency Procedures: Procedures for possible emergencies during crane use must be determined and the users must know these procedures. Fast and effective intervention in emergency situations is critical for safety.

Paying attention to these factors in the use and maintenance of Trolley Cranes is important to ensure occupational safety standards and to ensure the safe operation of the cranes.

We are always with our customers in after-sales customer service with our wide and high quality service. With our unlimited product spare parts stock, we provide the fastest service for the spare parts of the Trolley Crane.

Trolley Crane prices may vary depending on various factors. Factors such as lifting capacity, brand, technical specifications, intended use and extra features are among the factors that affect prices.