TRANSPORTATION EQUIPMENT

Conveying equipment has a wide scope and includes different types of equipment designed to suit various industrial needs. Here are some types of handling equipment:

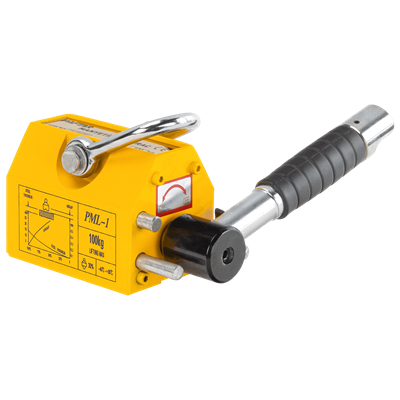

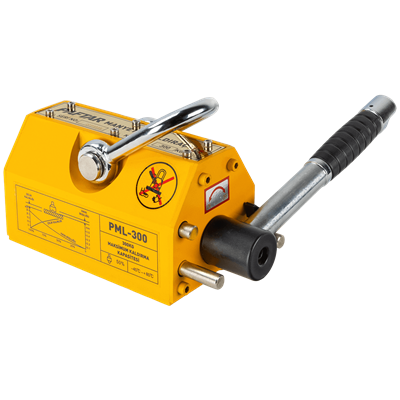

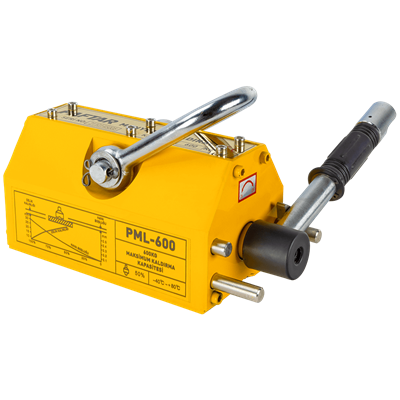

- Magnetic Levers: These are systems that create a magnetic field to lift and transport metal materials. It is used to lift heavy metal parts safely.

- Pig Carts: They are practical tools used in material handling and transport in industrial environments. They are designed to easily carry large and heavy loads with their high carrying capacity.

- Hydraulic Jacks: Jacks operating using hydraulic power are used to lift and transport heavy loads. It is frequently preferred in the automotive sector, industrial maintenance and repair works.

These various handling equipment facilitate material manipulation and transport operations by responding to the different needs of the industry.

The use and maintenance of handling equipment is critical to maintaining a safe and productive workplace environment. Here are the important factors to be considered in the use and maintenance of handling equipment:

1. Use in accordance with the Instructions for Use:

The operating instructions for handling equipment must be read carefully and used in accordance with these instructions. Operators must fully understand the limitations and safety features of the equipment.

2. Attention to Weight Capacity:

The weight capacity of the equipment must never be exceeded. Each piece of handling equipment has a specific carrying capacity and serious safety risks can arise if these limits are exceeded.

3. Safe Handling Procedures:

Loads must be placed and secured in accordance with safe handling procedures. Stable and safe handling of loads is critical to prevent accidents.

4. Maintenance Programmes:

Regular maintenance programmes for equipment should be established and adhered to. Maintenance is important to ensure operational continuity and prevent unexpected failures.

5. Controls and Monitoring:

Handling equipment should be inspected before each use and any faults or deficiencies should be reported immediately. Handlers should carry out regular checks on the operating condition of the equipment.

6. Knowledge of the Special Characteristics of the Equipment:

The special features and controls of each handling equipment are different. Users must fully understand and master the characteristics of the equipment they will be using.

Attention to these factors ensures the safe, efficient and long-lasting use of handling equipment, while at the same time maximising the safety of those using it.

We are always with our customers in after-sales customer service with our wide and high quality service. With our unlimited stock of spare parts, we provide the fastest service for spare parts of transport equipment.

_a4i3exultx (1)_b2ygrdezc3-optimized_89hm034wp0.png)

_12g52hnjgx.png)

_kf9kxonkzn.png)